lipstick hardness testing labs|lipstick testing : manufacturing Lipsticks were stored at room temperature for 24 hours before testing. A CTX texture analyzer with a 1.5 kg load cell was used with a TA-LC apparatus to perform a bend test. This test bends the lipstick a set distance and . WEBWhat Is Cortex Xpanse? Xpanse is an active attack surface management solution that helps your organization actively discover, learn about and respond to unknown risks in all .

{plog:ftitle_list}

1 de jan. de 2024 · Pokie Mate casino grants 30 free spins for up to 5 daily deposits of $30 or more, and 60 free spins for up to 5 daily deposits of $50 or more. The Weekend Bonus Mixer offer of Pokie Mate applies on several slots and will reward you with 50% bonuses up to $200 along with 20 free spins if you make deposits of $30 or more. If you deposit $50 .

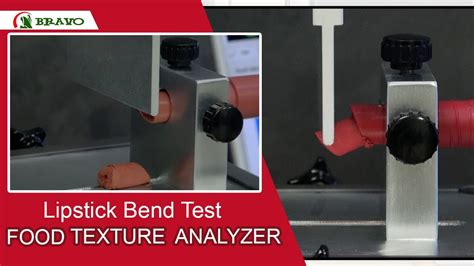

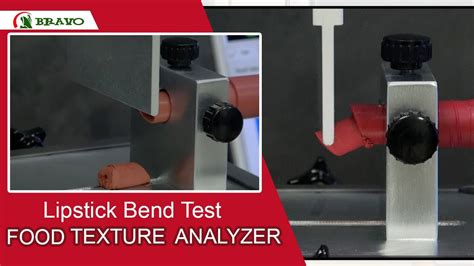

One cosmetic application for AMETEK Brookfield's CTX Texture Analyzer is the lipstick bend and hardness test, designed to determine the ideal firmness and stickiness of lipstick.The test can also be used to monitor hardness over a range of temperatures .The method for testing lipstick hardness is adopted from the ASTM Standard Method of test D1321-10. This is a penetration test that measures sample . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .

Lipsticks were stored at room temperature for 24 hours before testing. A CTX texture analyzer with a 1.5 kg load cell was used with a TA-LC apparatus to perform a bend test. This test bends the lipstick a set distance and .The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica-tion, and the customer requirements. After process of elimination, there are often only a few options left. . samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1 .

ATS employees are constantly receiving training on the latest Quality Standards ensuring that clients receive the most accurate results. Furthermore, our labs maintain a list of competency certifications for a variety of mechanical testing methods. We are ISO 17025 (A2LA) accredited to perform hardness testing methods in accordance with the bolded standards below: 🔬 Method 5: Laboratory Test. If you have a bit more money to spend on a hard water test, consider paying for a lab test. Laboratory testing gives the most accurate results. You’ll know your exact hard water reading, in both PPM and GPG. However, lab testing is the most expensive option, and we don’t think it’s essential when testing .

harga refractometer surabaya

application forces than the Silver Frost range. A Mann-Whitney U-test showed that this difference was significant at the P <0.00001 level. Each subject's applications of the same lipstick often covered a wide range of forces (Table I). Comparison of the application loads of two lipsticks, however, revealed thatOur metallurgy lab conducts Knoop Hardness Testing in conformance with the defined ASTM E92 and E384 standards. ASTM standards require that testers creating indentations at very low test forces are carefully constructed to not only accurately apply the test forces exactly at the desired location, but must also have a high-quality optical system to precisely measure the .A complete hardness testing service from ITA Labs with fast turnaround and competitive rates. Talk to our team - 01727 871 300. Home; Services; All Resources . All Resources; News; Case Studies; Blog; . All forms of hardness testing involve the application of a very hard material onto the surface of the sample being hardness tested, in order .Through hardness testing, ATS can determine vital information about a material’s limitations. The hardness testing lab technicians will also be able to provide insights into the material’s practical uses, as well as its potential for certain industrial applications. These tests also help confirm the component’s ability to function as .

Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials. When choosing materials for engineering purposes, this information is helpful.1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.A multi-discipline laboratory, our Metallurgy Testing lab offers professional support that services a variety of industries. Performance and qualification testing are intrinsic values our experts endow, providing comprehensible and technical details into the specific characteristics that influence the results presented. (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.

Note: It is recommended that the pre-test speed be the same as or less than the test speed for accurate trigger detection; for example, 1 mm/s test speed will require ≤ 1 mm/s pre-test speed. SAMPLE PREPARATION Condition the sample for temperature before testing. In this test samples were conditioned at 21°C overnight. PROCEDURE

Recommended for targeted testing of hardness level in drinking water. Reported results will include detailed, quantified analysis of hardness by SM 2340B (or equivalent). . collect your water sample, and prepare your sample for return .

The Hardness Testing Lab at ATS adopts contemporary A2LA/ISO 17025 accredited procedures and innovative technology to strive towards exceptional business practices for all of their clients. About Applied Technical Services. Applied Technical Services (ATS) was established in 1967 as a consulting, testing and inspection company servicing a wide .Dr. S. E. Beladi, PE Mechanics of Materials Lab P a g e | 1 Experiment Five- Principals of Stress and Strains Test Experiment Six (6) Hardness Testing Introduction Objective: To Study and evaluation of Surface hardness of different materials using Micro-Hardness testing Equipment, Vicker Methods. Apparatus: 1.The penetration test can also monitor hardness over temperatures that the soap may be subjected to during transportation and storage. Test temperatures must therefore be reported in the results. The soap penetration test can also indicate whether there are trapped air bubbles or a grainy texture seen as fluctuations in force as the probe comes .Leeb Hardness Test. The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.

Brinell Hardness Test. Similar to the Rockwell hardness test, a Brinell hardness test uses a heavier test metal and creates a larger indentation in the sample material, and measures only the indentation. . IMR Test Labs Headquarters. 131 Woodsedge Drive Lansing, NY 14882. Phone: (607) 533-7000, (888) 464-8422 Fax: (607) 533-9210. Analytical .

Buehler is a recognized leader in materials preparation, testing, and analysis, ensuring highly credible and practical insights. This source is valuable for readers seeking a thorough understanding of hardness testing techniques and their applications. 2. Academic Journal: “Advancements in Hardness Testing Techniques: A Review .The method for testing lipstick hardness is adopted from the ASTM Standard Method of test D1321-10. This is a penetration test that measures sample hardness. In the standard method, a penetrometer determines the distance of penetration when applying a specified force over a period of 5 seconds. The method described here is an alternativeIntroduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. . Infinita Lab is a marketplace of materials testing laboratories. We help engineers to solve difficult problems in a fast .

The MES Hardness Testing Laboratory performs hardness testing on metals, plastics, and other polymers using the Rockwell, superficial Rockwell, Brinell, and Shore durometer scales. ISO 17025 accredited. ASTM E18, ASTM E10, ASTM D785, ASTM D2240.

Testing Services for the Personal Care Industry. Microchem is an independent laboratory that provides testing services to formulators and manufacturers of cosmetics and other personal care products.. Each year, Microchem tests hundreds of products for shelf-life, freeze-thaw stability, photostability, and preservative effectiveness.. Cosmetic product testing . Requirement: 5 kg test weight calibrated to confirm within OIML Class M1 Tolerance ±250 mg. Remove the Hardness tester from the assembly by removing the four screws.

The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. . Infinita Lab is a marketplace of materials testing laboratories. We help engineers to solve difficult problems in a fast, cost-effective, and hassle-free manner. Contact info. Phone .

lipstick testing

Marketing program for the gaming industry

lipstick hardness testing labs|lipstick testing